- 550

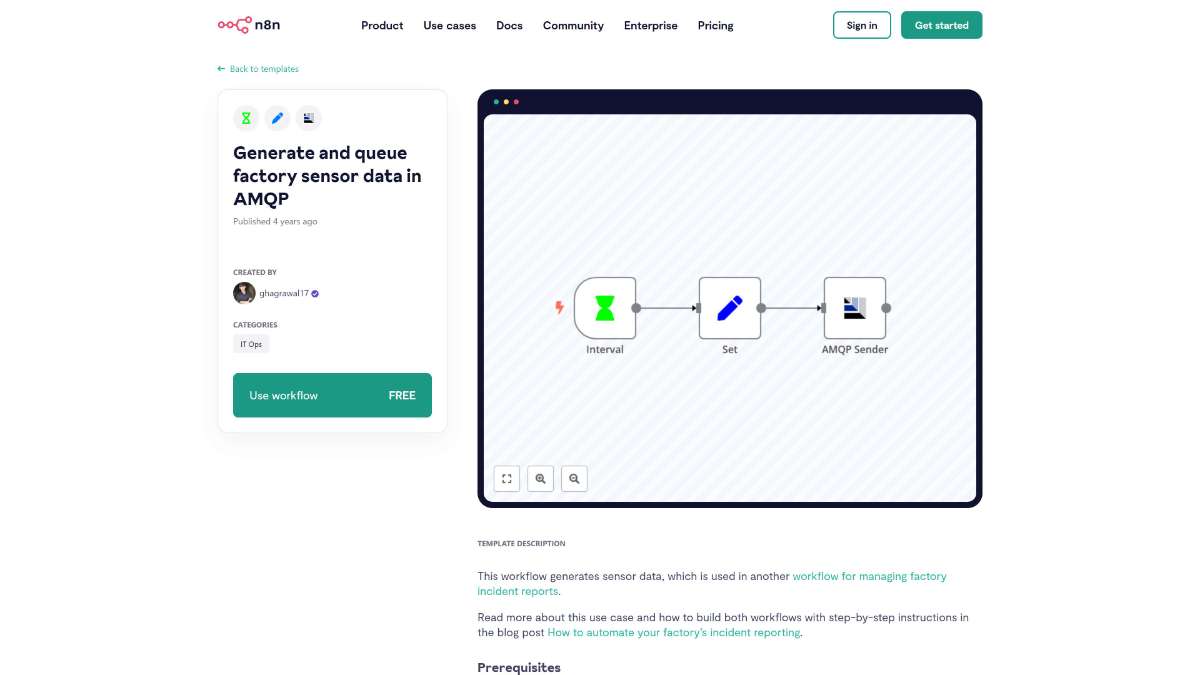

Generate and Queue Factory Sensor Data Using AMQP with n8n

Streamline data processing with sensor data generation and queuing via AMQP in n8n. Enhance efficiency with seamless integration and automation.

Streamline data processing with sensor data generation and queuing via AMQP in n8n. Enhance efficiency with seamless integration and automation.

Who is this workflow for? This workflow automates the generation of factory sensor data and queues it using AMQP. The queued data seamlessly integrates with another workflow designed to manage factory incident reports, enhancing operational efficiency and incident response..

This workflow is ideal for factory managers, automation engineers, and IT professionals involved in industrial automation. It suits teams looking to enhance their incident reporting systems by integrating real-time sensor data.

This workflow efficiently generates and queues factory sensor data using AMQP, enabling seamless integration with incident management systems. By automating data flow, it enhances real-time monitoring and response capabilities, contributing to a more reliable and efficient factory operations environment.

Automate customer creation in Chargebee, saving time and reducing errors. Use this n8n template to streamline your process with seamless integration.

Streamline your workflow by automating Hacker News data delivery to Airtable or SMS. Save time and ensure accuracy with this efficient n8n template.

Enhance customer insights by integrating Qdrant with Python in n8n. Streamline data processing and gain valuable insights effortlessly.

Help us find the best n8n templates

A curated directory of the best n8n templates for workflow automations.